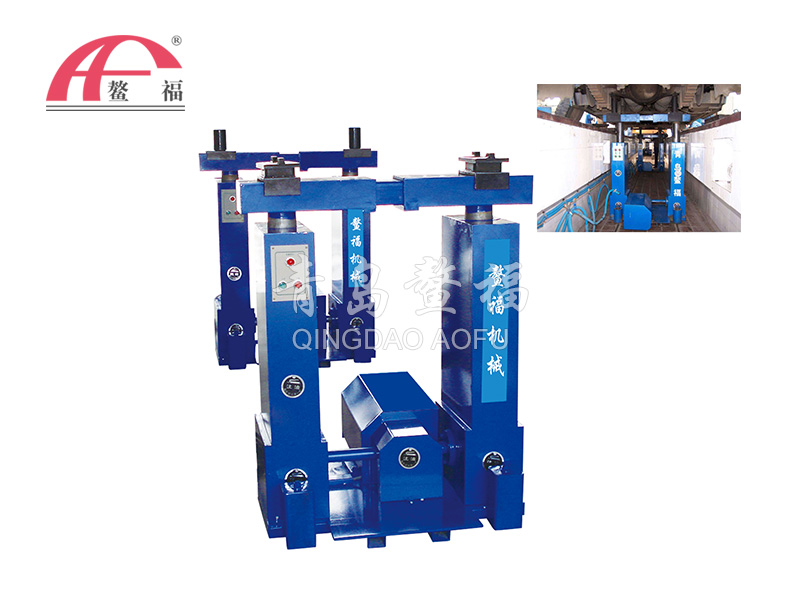

QJJ10-4C (single column lifting weight 2.5T) mechanical mobile four post bus lift, which adopts electric drive mode. Through electronically controlled operation, the worm turbine decelerates, the lead screw rotates, and the nut drives the bracket up and down. The pallet fork moves up and down with the carrier, supporting the car wheels to up and down.

1.Introduction

QJJ10-4C (single column lifting weight 2.5T) mechanical mobile four post bus lift, which adopts electric drive mode. Through electronically controlled operation, the worm turbine decelerates, the lead screw rotates, and the nut drives the bracket up and down. The pallet fork moves up and down with the carrier, supporting the car wheels to up and down.

QJJ20/30-4C ,QJJ45-6C (single column lifting weight 5/7.5T) mechanical mobile four post bus lift, which adopts electric drive mode. Through electronically controlled operation, the worm turbine decelerates, the lead screw rotates, and the nut drives the bracket up and down. The pallet fork moves up and down with the carrier, supporting the car wheels to up and down.

2.Introduction

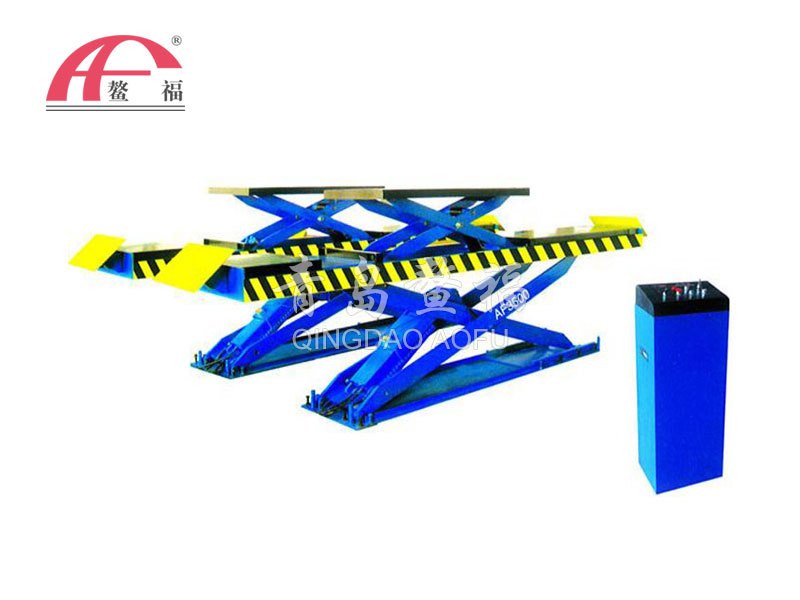

QJJ system lift has the characteristics of reasonable design, novel structure, strong and durable, large lift capacity, strong self-locking, flexible movement, wide range of models, convenient operation and maintenance. Due to its mobile operation, it can be installed indoors and outdoors. It is an ideal automobile lifting equipment for automobile maintenance and manufacturing industry to improve production efficiency, enhance warranty quality, and improve the working environment.

3.Technical Parameters

This equipment is suitable for the maintenance of buses, trucks, special vehicles and other vehicles in bus companies, large car manufacturing plants, large repair plants, factories and other places.

4. Product Details

5.Safety Device

1). There are steel safety nuts under the working nuts. When the working nut is suddenly damaged due to work wear or other reasons, the safety nut under the working nut supports it. Because of the steel ball rolling device, when the working nut is damaged, it falls on the safety nut, and the working nut is integrated with the safety nut, thus playing an insurance role.

2). At the upper and lower ends of each column, there is a lifting stroke limit device to ensure automatic shutdown when working overtime.

3). An electromagnetic clutch is provided at the top of the reducer motor to ensure that the lift brakes rapidly during the ascent or descent shutdown.

4). The walking wheel is equipped with hydraulic take-off and landing device. When the lift moves, pull the hydraulic jack bar to make the chassis leave the ground for easy movement. When lifting, step on the jack oil pedal or manual pressure relief handle to make the chassis land to ensure that the lift is safe, stable and does not displace.

6. Product Advantage

1). Large load capacity, leading in China

2). The four columns can be moved, simple and convenient operation

3). Column once formed, uniform weight, smooth operation

4). The lift is electric mechanical, 10 tons of bus lift using built-in guidance, 20/30/45 tons of bus lift using external guidance, bearing large capacity

5). The 10 ton bus lift adopts worm gear deceleration, and the 20/30/45-ton bus lift adopts planetary cycloid needle wheel deceleration, lead screw rotation, nut-driven towing frame and towing fork lifting

6). Humanized design, reasonable and beautiful

7). Have a product inspection and testing certificate;

8). Have the CE certificate

9).Have the ISO9001 certificate

10). The product all be insured by PICC

7. Operational considerations

1). The lift must be operated by a trained professional person

2). During the lifting, it is strictly forbidden to stand under the vehicle

3). Before the vehicle descends, all items under the vehicle must be removed

4). Keep the working environment clean

5). If you encounter a fault that cannot be handled, you should promptly notify the factory and the special distribution point of the factory, and be maintained by professionals

8. Warranty and after-sales service

1). Warranty period: The equipment is guaranteed free of charge for one year from the date of acceptance and signature, and the damaged accessories are provided free of charge. (Except for damage caused by human factors and other force majeure of the user).

2). After-sales service: From the time the equipment finds the problem to notify our company, our company will respond within 1 hour after receiving the call. Free telephone guidance is provided.